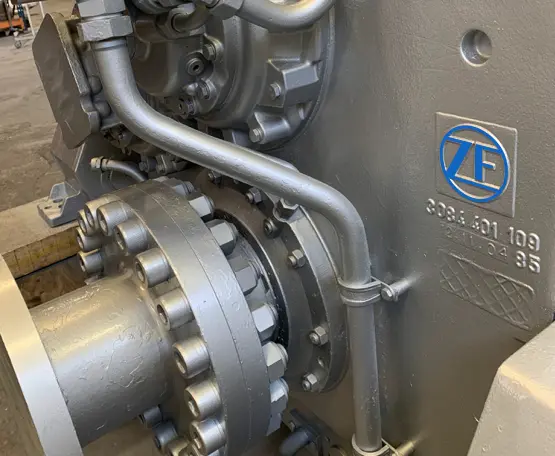

In modern yacht propulsion systems, the marine gearbox plays a central role in smoothly and efficiently transferring engine power to the propeller. Whether installed on a motor yacht or integrated into complex superyacht propulsion configurations, ZF gearboxes are engineered for reliability, precision, and long-term operational efficiency. As propulsion loads increase and onboard systems become more sophisticated, the importance of a high-quality marine gearbox has never been greater.

ZF Marine is globally recognised for its advanced gearbox solutions, supplying vessels ranging from compact yachts to large commercial and luxury fleets. A well-maintained ZF gearbox not only ensures seamless yacht propulsion but also protects engines, shafts, and propellers from unnecessary stress, vibration, and premature wear.

How ZF Gearboxes Improve Efficiency and Reduce Vibration

One of the defining advantages of ZF gearboxes is their ability to optimise torque transfer while minimising noise and vibration. Precision-cut gears, advanced clutch systems, and hydraulic controls allow marine ZF gearboxes to deliver smooth engagement and consistent power output across varying speeds and loads.

This reduction in vibration directly enhances onboard comfort, an essential factor for luxury yachts, while also improving efficiency. By reducing drivetrain losses and mechanical resistance, a yacht gearbox from ZF contributes to lower fuel consumption and improved overall propulsion efficiency, particularly during long-range cruising or dynamic positioning operations.

Check out our ZF gearbox services

ZF Oil Filter and Fluid Maintenance Intervals

Just like any engine, a ZF gearbox requires a strict and dedicated maintenance schedule and adhering to it is essential for long-term reliability. Routine lubrication maintenance is critical to the health of any marine gearbox, and ZF systems are no exception. Regular inspection with handle rotation of the slot-type filter, clockwise through 1 to 2 full turns (when installed), or the replacement of the ZF spin-on oil filter, at the interval recommended on the maintenance schedule, ensures that contaminants such as metal particles and debris do not circulate through the gearbox, preventing internal damage.

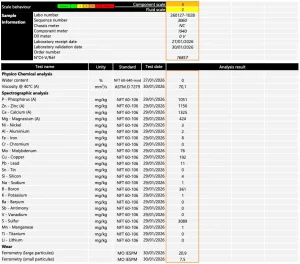

ZF oil and fluid change intervals vary depending on operating hours and vessel usage, but adherence to manufacturer recommendations is essential. Using the correct ZF oil grade and replacing filters at scheduled intervals significantly extends gearbox lifespan and maintains optimal hydraulic performance. Skipping oil maintenance is one of the most common causes of premature ZF gearbox failure.

Common Gearbox Issues and Early Warning Signs

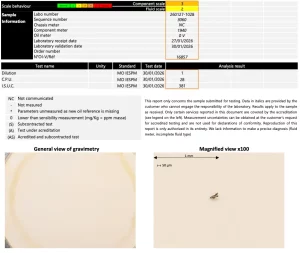

Even the most robust ZF marine systems can develop issues if maintenance is deferred. Early warning signs often include delayed gear engagement, abnormal noise, fluctuating oil pressure, overheating, or vibration felt through the drivetrain. Oil discolouration or metal residue discovered during a filter change may indicate internal wear requiring immediate attention. Performing an oil analysis at each oil change is strongly recommended to monitor wear progression and anticipate potential repairs before any major issues occur.

Addressing these symptoms early through professional inspection prevents minor faults from escalating into costly failures. Timely marine gearbox diagnostic checks are especially important before extended cruising, charter seasons, or high-demand operations.

The Role of ZF Official Service Dealers in Preventive Care

Authorised ZF marine dealers play a vital role in maintaining propulsion reliability. A certified ZF dealer has direct access to factory training, technical updates, diagnostic software, and genuine replacement components, ensuring work is completed to manufacturer standards.

Working with approved ZF official service dealers also guarantees accurate service records, warranty compliance, and proactive maintenance planning. In many cases, dealers can integrate gearbox inspections with other engineering services, such as a generator survey, creating a comprehensive preventive maintenance approach for yacht engineering teams.

Discover our range of official ZF parts

Yacht Gearbox Diagnostics and Overhaul Services Explained

Advanced gearbox diagnostic procedures allow technicians to assess internal gearbox health without immediate disassembly. Oil analysis, electronic monitoring, pressure testing, and vibration analysis provide valuable insight into wear patterns and component performance.

When necessary, full overhaul services involve disassembly, inspection, bearing replacement, clutch refurbishment, and recalibration. Professional overhaul of ZF gearboxes restores performance to factory tolerances and is often a cost-effective alternative to full replacement, particularly for larger yacht propulsion systems.

Choosing Genuine ZF Marine Parts for Reliability and Longevity

Using genuine ZF marine parts is essential to maintaining gearbox integrity and performance. Non-original components may not meet ZF’s strict material and tolerance standards, increasing the risk of premature failure or incompatibility with existing systems.

Authorised ZF dealers supply certified components, including seals, bearings, clutches, sensors, and the correct ZF oil filter for each model. Investing in genuine ZF marine parts ensures long-term reliability, protects asset value, and supports the consistent performance expected in high-end marine propulsion environments.

From efficiency and vibration reduction to long-term durability, ZF marine gearboxes form the backbone of modern yacht propulsion. Through proper maintenance, regular diagnostics, and support from authorised ZF official service dealers, yacht owners and engineers can ensure peak performance, reliability, and operational confidence across all cruising conditions.

Contact Navigair for official ZF marine gearbox maintenance