At NAVIGAIR, we remain closely aligned with manufacturer guidelines to ensure optimal performance, reliability, and even more focus on sustainable efficiency.

In an Official technical bulletin, mtu confirms that the famous Series 4000 diesel engine from M5xR through M93L, well known for their longevity and low maintenance even in extreme conditions and remote locations are absolutely suitable for low-load operations, thanks to their advanced engineering:

✔️ Dual-circuit (TE-split) cooling system

✔️ Sequential turbocharging

✔️ Triple-wall water-cooled exhaust manifolds

✔️ Common Rail injection

✔️ Cylinder deactivation systems

🌍 Running yacht engines at low-load contributes to fuel savings and emissions reduction, making it an environmentally conscious choice.

💰 It also offers a clear financial benefit to yacht owners and operators: less fuel consumption and reduced mechanical wear mean lower operating costs.

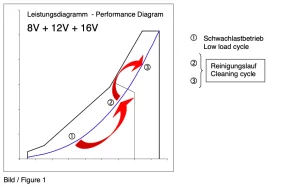

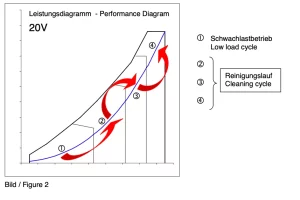

⚠️ That said, continuous operation below 15% of rated power is limited to 100 hours. To prevent excessive oil and/or carbon deposit formation in the engine, the engine shall perform a cleaning cycle of at least 20 minutes in total after such low-load operation mode. During this cleaning cycle the engine speed/load must be increased in steps until all turbochargers are in operation.

The attached diagrams respectively Figure 1 for the 8V,12V & 16V – Figure 2 for the 20V specifies the principle procedure of such cleaning cycle to be performed.

👉 At NAVIGAIR, we support you in understanding and applying these guidelines on your mtu-powered vessels — helping you combine performance, longevity, and efficiency.

📩 Don’t hesitate to reach out to our team for technical advice or support.